Can Quality Assurance Benefit Productivity? Can Quality Assurance Benefit Productivity? Nefeli Stylla QA & CSV Specialist Linkedin Quality Assurance: Is it really just a necessary Evil? Quality assurance (QA) is regarded by many as a necessary evil— vital for ensuring quality and compliance but accompanied by procedures and resource demands that constrain productivity. While these challenges contribute to QA’s perception as a necessary evil, they obscure that it benefits productivity in surprising ways. How do you define productivity? Productivity refers to the effective use of resources (such as time, energy, and materials) to achieve a particular outcome or goal. It measures how well inputs are converted into outputs and can be applied to individuals, teams, organizations, or even entire economies. As a multifaceted concept, productivity is measured differently depending on context. In the industry, it is typically measured using various metrics and key performance indicators (KPIs) that assess the effectiveness of production processes. How QA impacts on productivity Given the highly regulated nature of the pharmaceutical sector and the critical importance of product safety and efficacy, Quality Assurance practices are integral to ensuring compliance and maintaining the highest levels of product quality. Here’s how Quality Assurance impacts productivity in the pharmaceutical industry: Data-Driven Decision Making: Quality Assurance relies on data collection and analysis to measure and evaluate the performance of processes. This data-driven approach allows organizations to decide which processes need optimizing. It provides insights into where productivity can be improved. This data-driven approach allows organizations, especially those with a high level of digital and quality management maturity (CDER Quality Management Maturity | FDA), to make informed decisions based on real-time information and data analysis. Data insights from QA monitoring can guide strategic decisions that positively impact productivity. Detailed records provide valuable historical data that can support informed decision-making. Access to past performance metrics, productivity measures, project timelines, and financial records allows management to analyze trends, identify areas for improvement, and make strategic decisions based on a solid foundation. Risk Management: Quality Assurance practices in the pharmaceutical industry focus on identifying and mitigating risks in product development and manufacturing. Addressing potential risks early in the process allows companies to avoid costly issues and disruptions and foster a more efficient and predictable production cycle. Compliance measures are designed to mitigate risks associated with product safety and efficacy. By adhering to regulatory requirements, pharmaceutical companies can identify and address potential risks in the early stages of development. This risk mitigation reduces the likelihood of unexpected issues, delays, or product recalls, contributing to productivity and creating a more predictable manufacturing process. Employee Engagement: A mature quality management system often involves employees at all levels in the improvement process. Engaged and empowered employees are more likely to contribute innovative ideas and work more efficiently, positively impacting overall productivity. Process Optimization: Quality Assurance involves continuous process review initiatives. By optimizing manufacturing and testing processes, pharmaceutical companies can enhance efficiency and reduce the likelihood of errors. This leads to more streamlined operations, minimizing the time and resources required for production. Quality Assurance plays a crucial role in process optimization by focusing on improving the efficiency, effectiveness, and overall performance of various processes within an organization. Here’s how Quality Assurance contributes to process optimization and, subsequently, productivity growth: Quality Assurance thoroughly analyzes existing processes to identify inefficiencies and areas for improvement. By systematically reviewing each step in a process, QA and Production teams join forces to pinpoint bottlenecks, redundancies, and other issues hindering efficiency and productivity. Root Cause Analysis: Issues identified during Quality Assurance activities undergo root cause analysis to identify the underlying causes. This analysis enables organizations to go beyond addressing symptoms to tackle the fundamental reasons for inefficiencies and decreased productivity and facilitate more effective process optimization. Efficient Communication: Records serve as a reference point for communication within and outside the organization. When all parties have access to the same records, communication becomes more efficient, reducing the chances of misunderstandings or errors. Additionally, troubleshooting is more informed as records can be readily retrieved and reviewed at any given moment, thereby contributing to the elimination of information silos within the organization. All interested parties should have access to information in real-time, something that organizations using digital records have achieved, reducing communication time. This streamlined communication fosters a collaborative environment, enhancing overall productivity. Employees who feel connected and well-informed are 71% more likely to be productive. Continuous Improvement Culture: QA fosters a culture of continuous improvement within an organization, directly impacting increased productivity. This mindset encourages employees to regularly assess and seek opportunities to enhance processes. Compliance encourages a culture of continuous improvement. Regular evaluations and assessments to ensure compliance allow companies to identify areas for enhancement. This commitment contributes to a dynamic and adaptive organizational culture that fosters productivity. Continuous improvement ensures that optimization efforts are ongoing, aligned with changing organizational needs, and give organizations a competitive advantage by producing quality products and providing maximum value to customers. Audit Preparedness: Well-organized, comprehensive records facilitate a smoother process. Whether the audit is internal or external and conducted by regulatory bodies, having readily accessible records can significantly reduce the time and effort required for the audit preparation and the audit itself. Regulatory compliance involves maintaining thorough documentation and recordkeeping. This, in turn, facilitates faster and more efficient audits and inspections by both regulatory agencies and customers. Quick and successful audits reduce disruptions to operations, allowing the company to maintain productivity levels. Furthermore, in customer audits, an organization is actually proving that it is prepared and capable of satisfying customer needs. The QA team obtained customer feedback regarding the production process, quality control, and quality management. This ensures that the organization can be focused on its operational goals, business processes are not disrupted, and remain productive throughout the audit preparation and performance. Training and Skill Development: Quality Assurance initiatives in the pharmaceutical industry include training programs to ensure personnel are well-versed in regulatory requirements and quality standards. Well-trained staff are more likely to perform their tasks accurately and

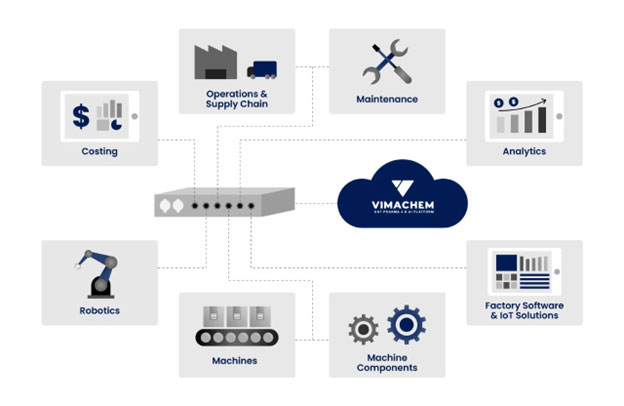

How Citizen Developers and Low-Code Platforms Are Shaping The Future of Pharma Manufacturing How Citizen Developers and Low-Code Platforms Are Shaping The Future of Pharma Manufacturing Ioannis Danias Continuous Improvement Specialist Linkedin Pharmaceutical manufacturing is on a transformative journey, and at its core are two dynamic forces: citizen developers and low-code software. These elements are converging to redefine how pharmaceuticals are manufactured, monitored, and optimized. In this article, we will examine the ways citizen developers and low-code software are reshaping the future of pharmaceutical manufacturing. The Current State of Pharma Manufacturing Compliance and Digital Silos The pharmaceutical manufacturing landscape combines process complexity and compliance regulations. The industry depends heavily on siloed software applications to manage daily operations, such as planning/scheduling, quality control, supply chain management, and quality management. Software Issues Traditional software applications are often costly, lack flexibility, and require skilled IT teams for development and maintenance, which can be challenging for pharma contract manufacturers where flexibility is required. Bottlenecks and Challenges Relying on standard software development can lead to bottlenecks, especially when rapid responses are crucial to address shifting market demands or accommodate changing regulatory requirements. The Rise of Citizen Developers Citizen developers are a unique breed of professionals in the pharmaceutical industry. They may not have formal software development training, but their in-depth knowledge of the industry’s processes, standards, and quality requirements, combined with the ability to leverage low code development tools, enable them to create software solutions that address specific business needs within their area of expertise (a valuable asset in pharmaceutical manufacturing, where minor deviations from standards can have serious repercussions). Though the knowledge base of the individuals may vary, plant managers, supervisors, shop floor workers, and anyone else with a basic grasp of technology can become a citizen developer and continuously digitalize their business processes, ensuring improved product quality, increased efficiency and time to market. The Collaborative Power of Citizen Developers and Traditional IT Departments The future of pharmaceutical manufacturing hinges on close collaboration between citizen developers and professional IT teams, with process professionals bringing their domain knowledge to the table and citizen developers their expertise in IT scalability, and advanced integration. Mentoring and Knowledge Sharing IT departments have a crucial role in mentoring citizen developers, ensuring that the low-code development applications they create align with long-term organizational objectives. Knowledge sharing between these two groups fosters an environment of innovation and collaboration. Holistic Solutions This collaborative approach often leads to the development of comprehensive solutions that benefit the entire organization. It bridges the gap between operational needs and technical capabilities and ensures that every application aligns with the overall business strategy. Low-Code Development Platforms in Pharma Manufacturing Low-code software platforms have emerged as a revolutionary force offering a user-friendly, visual development environment, allowing both professional and citizen developers to create applications with minimal traditional coding. Here are five compelling reasons why these solutions are a game-changer for pharmaceutical manufacturing: Agility Enabling rapid application development and modification – critical when faced with constantly changing market dynamics and regulatory shifts. Efficiency Creating applications tailored to specific manufacturing processes increases operational efficiency and reduces the need for manual intervention, thus releasing human resources to other tasks. Cost-Effectiveness Compared to traditional software development, low-code solutions are more economical due to lower vendor support costs, one-off implementation, and free creation and customization of reports. In addition, these applications effectively leverage expertise that already exists within the organization. Quality Assurance These applications utilize a deep understanding of manufacturing processes to seamlessly align with industry standards. Features like version control ensure that the latest approved versions of processes and documents are in use, while built-in audit trail functionality enhances changes and activity tracking across the tool. Compliance and Cybersecurity These two critical pharmaceutical industry concerns are addressed by built-in compliance features and robust security measures integrated into low-code development platforms. Security features, such as role-based access control and encryption, minimize the risk of unauthorized access, while storing data either on-premise or in the cloud ensures that compliance standards are met according to different IT policies. Pharma Manufacturing in the Future Customized Platform Workflows Customized workflows combined with low-code development platforms create custom business applications that perfectly fit the plant’s workflows and processes. These applications can be used to improve efficiency, increase compliance, and streamline operations. Quality Control Reinvented Low-code platforms revolutionize quality control processes, making inspections more efficient, ensuring that pharmaceutical products meet quality standards, and instantly reporting deviations. Real-Time Monitoring Low-code platforms allow manufacturing processes to be monitored in real time, giving stakeholders unprecedented visibility into operations through digital transformation. This permits immediate intervention if a problem arises and promotes fast, well-informed decision-making. Rapid Response to Change The pharmaceutical manufacturing industry is no stranger to rapid regulatory changes, market dynamics, and consumer demands. When certain business processes are based on low-code platforms, business users have the agility to respond to these changes effectively without the need for app development. Supply Chain Visibility Pharmaceutical manufacturers can improve supply chain visibility and predict potential delays and unplanned deviations with low-code applications. This, in turn, limits the effects of disruptions and ensures a constant supply of materials. The Road Ahead Regarding the future of pharmaceutical manufacturing, one thing is clear: Adaptability is key! Citizen developers and low-code platforms will collaborate to drive innovation and efficiency in our highly regulated industry. Companies will invest in training, support, and resources that enable citizen developers to impact pharmaceutical manufacturing and fully realize their potential. By implementing a low-code platform, the pharma company gains a competitive advantage that allows it to upgrade traditional development methods and legacy systems. Conclusion The dynamic duo of citizen developers and low-code platforms is reshaping the future of pharmaceutical manufacturing in a collaboration that provides a compelling solution to the issues of complexity, compliance , and the need for rapid adaptation. The benefits of flexibility, cost-effectiveness, and customized solutions are becoming transparent. By implementing automated procedures, low-code platforms accelerate the development process, yielding insightful data from business users and supporting data-driven decision-making

WHAT YOU NEED TO KNOW A COMPREHENSIVE GUIDE TO THE DRUG SUPPLY CHAIN SECURITY ACT (DSCSA) What You Need to Know A Comprehensive Guide to the Drug Supply Chain Security Act (DSCSA) George Gketsios Senior Manager – Solution Consulting Linkedin Introduction: The pharmaceutical industry is a lucrative yet highly regulated field, especially concerning drug supply. In this comprehensive guide, we delve into the Drug Supply Chain Security Act (DSCSA), a federal law signed in 2013 to bolster drug supply chain security. We cover its significance, implementation phases, the importance of 3T documentation, reasons for aggregation, and exemptions under this act. What is the Drug Supply Chain Security Act (DSCSA)? The DSCSA is a crucial federal law enacted in 2013, designed to enhance the security of the pharmaceutical supply chain. By establishing a comprehensive tracking and tracing system, it enables monitoring prescription drugs from manufacturers to end-users. The collaboration of stakeholders such as manufacturers, repackagers, wholesale distributors, dispensers, and third-party logistics providers is essential for its success. DSCSA’s Final Implementation Phase: Scheduled to take effect on November 27, 2023, the final implementation phase demands that all participants in the pharmaceutical supply chain have systems in place to trace prescription drugs at the package level. This entails ensuring each package has a unique identifier, which must be updated as it progresses through the supply chain. Understanding 3T Documentation: Critical to DSCSA compliance, 3T documentation comprises Transaction Information, Transaction History, and Transaction Statement. These standardized pieces of information accompany every prescription drug transfer within the supply chain. Transaction Information includes product details, strength, dosage form, package size, and the National Drug Code (NDC) number. Transaction History encompasses all product transactions, while the Transaction Statement confirms the product’s legitimacy and non-counterfeit status. The Importance of Aggregation: Aggregation, the process of combining identical products into larger units, plays a vital role in DSCSA adherence. For packaged products or multi-product kits, aggregation facilitates the tracking and tracing of each unit with unique identification numbers. This process streamlines tracking and updating identifiers, making the monitoring of prescription drugs more efficient. Exemptions Under DSCSA Requirements: While the DSCSA encompasses most prescription drugs, some exemptions apply. Compounding pharmacies preparing drugs for individual patients based on prescriptions and over-the-counter drugs not in prescription form are exempt from the Act’s provisions. Conclusion: The Drug Supply Chain Security Act (DSCSA) is a pivotal piece of legislation aimed at enhancing the pharmaceutical supply chain’s security. As a production manager in the pharmaceutical industry, understanding the DSCSA is essential to ensure compliance with the law. This guide equips you with the necessary knowledge to take the right steps and ensure your organization’s full compliance with the Act. Stay informed, be prepared, and uphold the integrity of the drug supply chain. Contact us READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS? READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS? Vimachem Manufacturing Analytics – OEE The Manufacturing Analytics – OEE module is an intelligent Pharma OEE Cloud solution that allows you to collect, store and visualize data across your site / enterprise and apply AI algorithms to optimize production efficiency and product quality. Get started with real-time manufacturing analytics today! Book a Demo

The “Hidden Pharma Factory” The “Hidden Pharma Factory” George Gketsios Senior Manager – Solution Consulting Linkedin What is the Hidden Factory? The term “hidden factory” refers to the unnoticed or “hidden” parts of a manufacturing process that affect product quality or reduce the efficiency of the plant operation. The hidden factory is the set of activities within the process that reduce the quality or efficiency of a manufacturing process and is not apparent to managers or others seeking to improve the process. The hidden factory represents the untapped capacity of your manufacturing plant and, thus, the loss of revenue. Fully utilizing your hidden factory means around-the-clock perfect production – manufacturing only finished products as efficiently as possible, with no downtime, every hour of every day. Hidden factories, as the name implies, are difficult to spot. They are the product of a series of minor, unplanned modifications and the culture that develops around them. Since enterprise resource planning tools are fitted to hidden factories rather than being employed to deactivate them, it then penetrates the operations architecture. To be able to “see” the hidden factory in an organization, you need to learn what waste is and understand that waste in any business, manufacturing, or service can have a significant negative impact on the bottom line, top line, employee morale, shareholders, and, most importantly, the customer. Many manufacturers are surprised to learn that they have more capacity in their hidden factories than they are using in their actual factories. The hidden factory represents the untapped production potential within your current plant. Why is discovering the hidden factory important for the manufacturing process? Ignoring the hidden factory in the manufacturing process can lead to a loss of profitability because the waste consumes resources that should be allocated to the factory floor. It also diverts capital to unnecessary new manufacturing equipment, absorbing working capital from things that could be used to improve processes and grow the business. The ability of the manufacturers to improve throughput without further capital investment is the hidden factory’s most important advantage. On the factory floor, tapping into your hidden factory can reduce or even eliminate outsourced production over time. Benefits of unlocking the hidden factory The main advantage of uncovering hidden factories is the increased throughput without additional capital investment. Simply put, it’s about getting more out of what you already have. The benefits of unlocking hidden factories are high and include improving quality, allocating fixed costs to increasing output, improving capacity planning, and increasing the throughput of existing plants. Digital innovations such as the Internet of Things (IoT), artificial intelligence (AI)/machine learning technologies, and hybrid systems can help businesses leverage the data they generate to increase profitability, manage quality, and achieve continuous improvement goals. Furthermore, they help businesses to address issues and implement solutions faster with new technology that notifies you when parameter limits or key performance indicator (KPI) control limits are exceeded. Integrating industry-leading KPI dashboards helps to track, trend, monitor, compare and improve ongoing operations. Discovering your hidden factory through Digital Transformation The journey to discover the hidden factory is both exciting and difficult. It will test the continuous improvement mindset when striving to get a better understanding of waste in the manufacturing process, reducing waste and uncovering inefficiencies. Unlocking the hidden factory should occur concurrently with digital transformation. Data collected by selected equipment with edge devices and IoT sensors is extremely valuable because it provides real-time, accurate information to help search for bottlenecks. When combined with digital transformation, the changes made along the way are immediately measurable in real time. Managers can devote more time to process improvement at the start of a project because they can access data more quickly and accurately. Entire industries have sprung up to assist firms in mitigating the effects of the hidden factory. How calculating Overall Equipment Effectiveness (OEE) can help to tap into the hidden factory The Overall Equipment Effectiveness (OEE) KPI is the fundamental metric for determining how productive your projected production time is as a percentage. OEE is the gold standard for measuring manufacturing productivity. Overall Equipment Effectiveness (OEE) calculation in the production process has evolved into a great tool and industry-leading KPI for maximizing machine uptime. OEE is the gold standard for measuring manufacturing productivity. This metric comprises critical data points such as Availability, Performance, and Quality. When you multiply each of these measurements (with availability just considering the projected production time), you get the overall efficacy of your equipment on the shop floor. Simply put – it identifies the percentage of manufacturing time that is truly productive. OEE calculation can show the actual potential of your manufacturing equipment, and you may discover that investing in additional IoT devices and sensors, along with smart data analytics, can considerably enhance production capacity in a matter of months. This approach can save you money on pricey upgrades or replacement of manufacturing equipment that isn’t completely obsolete. By measuring OEE and the underlying losses, factories gain important insights into how to improve the manufacturing process systematically. OEE is the single best metric for identifying losses, benchmarking progress, and improving the productivity of manufacturing equipment (i.e., eliminating waste) and helps manufacturers tap into the hidden factory. It can decrease overtime or eliminate outsourced production. A smart factory can achieve long-term success and maintain a competitive advantage by making decisions based on performance data. As a baseline, OEE can be used to track progress over time when eliminating waste from any given production asset. OEE is one part of a balanced approach to improving productivity, as solely focusing on OEE can lead to overproduction, running equipment beyond rated parameters, overstaffing processes, and other counterproductive behaviors. How Vimachem Manufacturing Analytics & OEE solution can help you The Vimachem Manufacturing Analytics & OEE solution specializes in finding inefficiencies and tracking the actual line speeds and other site data in real-time by leveraging Industrial Internet of Things (IIoT) connectivity. Monitoring and analyzing machine data will increase operational efficiency and performance, bring instant

The impact of digital boards on production performance The impact of digital boards on production performance George Gketsios Senior Manager – Solution Consulting Linkedin The pharmaceutical manufacturing industry is no stranger to using whiteboards for daily management, pulse meetings, improvement work, and lean tools. Digital boards can present production data and insights from machines, sensors, and systems in a user-friendly way. They help pharma manufacturers monitor and optimize production quality and efficiency. Creating a visually instructive work environment is the foundation of any successful lean manufacturing initiative. In the manufacturing world, if one cannot keep up with the shop floor activities, it can lead to higher risks to safety, quality, and productivity. So, digital boards help shop floor management save time by facilitating visual communications and control. What is visual management? Visual management is important to any well-communicated working environment. It ensures your key information is communicated quickly and easily. The impact of production digital boards on the shop floor cannot be underestimated as it allows managers to identify quality issues early on and take corrective action before they become larger problems. Digital boards in manufacturing plants that include logos/symbols alongside clear and readable text help maintain constant awareness at every turn and make sure production efficiency is increased by making informed decisions quickly. At the same time, it keeps everybody on the shop floor informed about and focused on important metrics, action plans, and directions in real-time. How is production data displayed in the form of Digital Boards in a Manufacturing Site? Factory display boards are an important tool for monitoring progress made in the manufacturing process and the status of the different production steps. This visual information provides a quick and simple overview that allows people throughout each work cell to see valuable information about what’s happening around them, whether it’s production or supply rates, inventory levels, or pending action plans. Factory display boards are a digital communication tool in pharma manufacturing companies that provide important production data to those who need the information. Functionality often comes linked to sources such as factory-wide monitoring systems, which update data for all employees’ needs. Hence, everyone knows what tasks need attention next or where any problems may arise. Most importantly, they contribute to building a culture of operator inclusion, visibility, continuous improvement, and employee ownership of the process. Production Display Boards The production displays can be simple or complex, depending on what information range will efficiently give access to visual insights that will benefit the company. For example, a shop floor worker may only need a few metrics, but there’s really no limit to how much data from a production line can be included. However, they can become complicated with countless pieces of information provided by those working on-site about how production progresses throughout a business day. Production dashboards usually use IoT technology and monitoring devices, data from autonomous machines, or other connected equipment. These are then made visible on this screen throughout the shop floor, so employees know precisely what to do at any given time! This way, there’s no guesswork involved, processes will follow the schedule more easily, and everyone will be more productive in less time! Shop Floor Data Display Boards Shop floor managers need to be able to use visual information about all of the manufacturing lines. Therefore, shop floor display boards should include critical information and all relevant data that allows the floor manager to know when something goes wrong with production lines. With up-to-date information about the status of each facility’s workload, it becomes easy through production monitoring to identify any problems when they arise and take corrective actions in order to maintain consistent output levels across all production lines. The Head of Production needs this tool in order to provide clear visual cues about where products are being made. What tools/machines exist at different locations within their assigned space and how many employees work there daily will help with forecasting future demands if enough notice has been given beforehand. In addition, the tool helps the shop floor manager to decide quickly and correctly where they should focus their attention at any given moment during the shift. To ensure production plans are executed as efficiently and accurately as possible, the floor manager must have a solution that provides visual information about where products will be made. How are Digital Boards Helping Lean Manufacturing? Lean manufacturing means having a clear understanding of all losses (waste) at any given process and if there are areas that could be improved. It achieves this through the structured use of several tools like visual management, value stream mapping, 5S, kaizen, SMED, Kanban, etc. These would not only increase productivity but also lead to improved communication and employee ownership. Lean manufacturing is not just about the process of making products but also includes managing your workplace to produce efficiently. A key component for successful lean management involves creating a visual learning environment that informs and encourages workers and makes them more productive as they progress through each step during the following four stages of this learning: Planning Production Quality control on goods produced Improvement, if necessary, until finally achieving approval, where those improvements may then be implemented into new product development strategies A visual workplace is absolutely necessary for a continuous improvement culture! The four stages above are facilitated with visual and dashboard displays, and the time needed to transmit the information is reduced. Creating a visual learning environment for workers is a key component of successful lean manufacturing. What are the most effective Shop Floor Digital Boards in Pharma Manufacturing? With so many different types of solutions out there, there is a range of key performance indicator (KPI) combinations that can be seen to display important information. There is no universal display board layout that works for all companies, which can show both constant and rotating KPIs for departments, to ensure they get the most from their people and solutions. Custom solutions that meet the specific needs of

Digital lean manufacturing in the industry 4.0 era Digital lean manufacturing in the industry 4.0 era George Gketsios Senior Manager – Solution Consulting Linkedin Origins of Lean Manufacturing Historical Overview The lean manufacturing principles emerged in the industrial world shortly after WWII when Toyota decided to rebuild its operations from scratch by combining a set of pre-existing tools and practices from the Henry Ford era with a new mindset of zero tolerance towards the concept of waste throughout its operations. That was the birth of the Toyota Production System. Since then, several key performance indicators (KPI), with the most fundamental one being the Overall Equipment Effectiveness (OEE), concepts, and lean tools have been developed, utilized, and continuously updated all over the world in the direction of optimizing manufacturing operations, eliminating waste, and driving equipment effectiveness, productivity, and profitability levels. Several decades on, a wide range of lean manufacturing methodologies have been created and subsequently evolved to implement daily, weekly, monthly, and annual routines in the manufacturing industry. Evolution Over the Years More recently, these methodologies have been combined with new managerial tools and concepts that place industrial operators at the heart of the journey of operational excellence, aiming to instill a continuous improvement culture in manufacturing shop floors and beyond. Results & Trend Numerous companies and their plants have benefitted from the ever-growing knowledge in this field, and this has led to products of ever-growing quality with low life cycles and low cost being offered to customers worldwide. Arguably, this trend is expected to continue pushing factories to their capacity and productivity limits in the future throughout the whole range of the manufacturing industry. Need for Reliable & Accurate Data Common Ground No matter which particular methodology is chosen for implementation, whether it is a customized solution based on Just In Time, TPM, IWS, etc., or a readily available lean manufacturing routine, they all share the same basic lean principles and, therefore, the same common basic prerequisites in order to bring the anticipated results. Navigating Through Losses One of the most important requirements in the operational excellence journey is access to complete, accurate, and reliable data regarding the current level of operation in every part of the shop floor at any given time. The opportunity to set the proper direction in driving decision-making, addressing the correct issues, focusing on the most impactful actions, and monitoring their effect on the process productivity depends heavily on the ability to retrieve, analyze, and archive raw data for every step of the process at any given moment. Traditional Data Collection & Analysis In traditional lean improvement projects, raw data was captured in a sporadic fashion using either SCADA systems incorporated in industrial machinery or the use of paper template documents that were completed manually by operators and supervisors. As a result, the data was neither complete nor detailed enough in most cases. The subsequent analysis involved a time-consuming process that was either manual or facilitated in a Microsoft Excel environment, along with several assumptions that had to be made to calculate the OEE and draw meaningful business insights from it. These lean manufacturing practices are shifting rapidly with industry 4.0. Information Technology Breakthroughs Over the last decade, breakthroughs in technology associated with what we nowadays call “Industry 4.0” have changed the scenery drastically. They have generated opportunities that were out of reach in the past to such an extent that companies now shift their focus from automating individual tasks to developing end-to-end digital transformation strategies. IoT The Internet of Things (IoT) allowed the connection of different pieces of equipment under one electronic management system, which paved the way for remote controlling and gathering of operational data in an automatic way at all times. Big Data Big Data analytics has led to great opportunities in gathering, organizing, and analyzing large volumes of data towards identifying not only immediate business insights but also underlying trends and patterns that allow now more than ever for more preventive action. Cloud Computing Cloud computing and cyber-physical systems are taking automatic processes and real-time physical intervention to a new level as computers can control deviations in the physical systems, apply proposed actions and immediately monitor their impacts on the system. Artificial Intelligence Additionally, artificial intelligence algorithms have been employed to go through a vast volume of accumulated data, action plans, and their impact on the process in order to “train” the system through machine learning to be able to propose immediate solutions and actions to real industry problems thereby enhancing and speeding up troubleshooting routines and evaluating different potential improvement scenarios. Capturing the True Value of Digital Transformation Through Industry 4.0 Direction Setting The fourth industrial revolution has allowed operators and managers, who now have the tools required to automate a large part of their day-to-day duties, to provide valuable and insightful feedback in real-time and quickly identify the real pain points of their processes and equipment. Digital technologies shift their focus in the right direction of tackling the most crucial issues in the manufacturing process and the equipment with the most value-driven approach for the overall business, thereby triggering a digital lean transformation. Decision-making Decision-making is now faster and more accurate than ever-changing management practices throughout the organization as different developments can be applied, tested, and adopted with the minimum level of waste in the process with the highest rate of success. This way, industrial operations on the shop floor can be optimally streamlined, and improvement can be achieved at an accelerated pace and with minimum effort. Lean initiatives were never easier to implement. World-class manufacturing companies have recognized the importance of digital transformation as a competitive advantage in the current era. Vimachem OEE & Analytics Vimachem’s OEE & Analytics solution offers a set of Industry 4.0 digital tools and KPIs specially developed to navigate today’s pharma production processes through current and future challenges in the ever-lasting journey towards digital lean and operational excellence. Attend a demo and find out how READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS?

Pharma 4.0 Technologies in OEE Monitoring Pharma 4.0 Technologies in OEE Monitoring Ioannis Danias Continuous Improvement Specialist Linkedin Industry 4.0 has significantly transformed the pharmaceutical manufacturing sector. The integration of digital technologies into manufacturing processes is one of the most significant changes, enabling real-time monitoring of production processes and ensuring that everything runs smoothly and efficiently. Overall Equipment Effectiveness (OEE) is a key performance indicator for pharmaceutical production and packaging since it provides a measurement of equipment and process productivity and performance. In today’s fast-paced and intensely competitive business environment, utilizing technology for accurate OEE monitoring is becoming increasingly crucial for pharmaceutical organizations. It helps to maintain their competitive edge by monitoring processes in real-time and making data-driven decisions to enhance their operations continuously. Challenges of Monitoring Overall Equipment Effectiveness Monitoring OEE is a crucial aspect of manufacturing operations, but it can present a number of obstacles. These obstacles can make it challenging to obtain accurate OEE measurements and impede the capability to enhance production processes continuously. A. Difficulty in Acquiring Precise Data One of the most challenging aspects of OEE monitoring is collecting reliable data. A number of factors, such as equipment malfunctions, manual critical data entry errors, and a lack of standardization in data collection processes, can cause this. These factors may result in misleading OEE calculations and a skewed understanding of production performance. B. Inadequate Production Process Visibility Insufficient visibility into manufacturing processes is another obstacle to effective OEE monitoring. Without a clear view of the manufacturing line, it can be difficult to determine the root causes of production losses and the areas needing improvement. This can lead to missed opportunities for improvement and a decline in production efficiency as a whole. C. Labor-intensive Manual Calculations Lastly, OEE monitoring can be time-consuming and labor-intensive, particularly when manual calculations are utilized. This can result in delays in data analysis and reporting, making it difficult to identify and resolve production issues in a timely manner. In addition, manual calculations are susceptible to error, which can further compromise the precision of OEE measurements. In conclusion, the obstacles associated with OEE monitoring can make it difficult to obtain accurate and actionable production performance insights. Therefore, it is essential to implement technology that automates data collection and analysis, provides real-time visibility into production processes, and simplifies OEE calculation to overcome these obstacles. Industry 4.0 Production Monitoring Main Benefits By monitoring the production process in Industry 4.0, manufacturers are able to identify bottlenecks and inefficiencies quickly and implement corrections. This ability reduces downtime and increases overall productivity, resulting in a more productive manufacturing process. By identifying inefficiencies and taking prompt corrective action, manufacturers can reduce waste and downtime, resulting in long-term cost reductions. A. Computerized IIoT-Driven Data Collection and Evaluation The ability to collect real-time data is another important advantage of production monitoring in the Industrial Internet of Things (IIoT). In the past, manufacturers relied on batch reporting and manual data collection methods that were time-consuming and prone to errors. Now, in the industry 4.0 era, manufacturers can collect and analyze data with the click of a button. This information can be utilized to make informed decisions regarding production processes and identify areas for enhancement. B. Improved Collaboration Moreover, real-time data can facilitate improved collaboration and communication between departments and stakeholders in the manufacturing process. Especially production and maintenance departments need to make synchronous decisions, even based on the last minute shop floor changes. C. Assigning and Monitoring Tasks Using a software solution to manage tasks has proven beneficial for businesses operating multiple shifts, resulting in significant improvements in collaboration between operators who do not see each other or their manager due to different working hours. D. Predictive Maintenance Monitoring production enables predictive maintenance since, by analyzing data, manufacturers can identify patterns and predict when a machine is likely to fail. Corrective action can be taken in advance to reduce downtime and repair costs while also improving overall equipment efficiency. E. Improved Quality Improved quality control is one of the most significant advantages of production monitoring in Industry 4.0. By monitoring production processes in real-time, manufacturers are able to quickly identify any quality issues and take corrective action before they escalate. This could include adjusting machine settings, reworking or scrapping a batch of products, or making other changes to the production process to improve quality. This reduces waste and improves product quality, resulting in increased customer satisfaction. Utilizing Technology for OEE Monitoring The benefits of OEE monitoring over conventional manual data collection and analysis techniques are numerous. They include enhanced precision, productivity, insights, real-time visibility of production processes, precise and reliable OEE calculations, and enhancement of decision-making abilities. A. Computerized Data Collection and Evaluation One of the most significant benefits of utilizing technology for OEE monitoring is the ability to automate the process of data collection and analysis. Data from multiple sources, such as Industrial Internet of Things (IIoT) sensors, can be collected in real-time with the help of technology. B. Enhanced Precision, Productivity, and Insights Automating data collection and analysis yields numerous advantages, including enhanced precision and productivity. There is no risk of human error with automated data collection, and the data is always consistent and up-to-date. This information can then be processed and analyzed utilizing machine learning algorithms to produce accurate and actionable production performance insights, that would otherwise be difficult or time-consuming to obtain manually. C. Visibility of Production Processes in Real-Time Another benefit of utilizing technology for OEE monitoring is visibility into production processes using real-time production data. Using technology, manufacturers can monitor production processes in real-time, providing a clear view of production line performance. This visibility enables manufacturers to identify problems as they arise and take swift action to address them. With real-time visibility, manufacturers can make informed decisions regarding how to increase Overall Equipment Efficiency. D. Precise and Reliable OEE Calculations Additionally, technology can simplify and improve the precision of OEE metrics. Automated data collection and analysis to calculate OEE more consistently and in real-time. This

Cell and Gene Manufacturing – Why Paper is the Enemy of Quality Cell and Gene Manufacturing – Why Paper is the Enemy of Quality Vivi Korba Upstream Engineer Cell and gene therapy companies are emerging from years of laboratory-scale development through preclinical tests and pivotal clinical trials, ultimately reaching FDA approval and product commercialization. As a result, the Cell, and Gene Therapy (CGT) market is expanding rapidly, with a Compound Annual Growth Rate (CAGR) of over 30% expected for the period 2021−2025. This increase is attributed to the potential of CGT to treat and potentially cure debilitating diseases. These include relapsed or refractory B-cell acute lymphoblastic leukemia, spinal muscular atrophy, and Leber congenital amaurosis. What is Cell and Gene Therapy? CGT is a subfield of biomedical research and an emerging field of experimental medicine that plays a vital role in modern healthcare due to benefits such as cell-cell interaction, remodeling, regenerative capacity, and gene regulation. CGT involves extracting cells, proteins, or genetic material (DNA) from the patient (or a donor) and altering these to provide a highly personalized therapy, which is injected into the patient. This technique can potentially address complex diseases, such as motor neuron disease, cancers, and many rare disorders for which there are currently no effective treatments. It seeks to prevent, treat and cure rare disorders and acquired infections, as well as to reduce the underlying causes of these diseases, and may offer longer-lasting effects than traditional medicines. Market Overview Recent years have seen a steady acceleration in the number of CGT treatments on the market. More than 75 will be launched (including individual markets, such as Japan, Russia, and South Korea) by the end of 2022. Many more are in development, offering the hope of revolutionary healthcare. The US dominates the global CGT market, with the highest absolute growth of more than 500% and a CAGR of around 36%. GROWTH FACTORS An exponential rise in the clinical pipeline, coupled with a rising number of regulatory approvals for advanced therapies, has mainly driven the market. Market participants are focusing efforts on boosting their market presence, considering promising growth opportunities in the contract development of cellular and gene-modified therapies. Also, biomanufacturers are signing strategic alliances with contract manufacturers to accelerate the R&D of their candidate programs. KEY HIGHLIGHTS According to a report from the American Society of Cell & Gene Therapy, the industry will rise as more products are developed, used more frequently, and tested in clinical studies. According to the BioPharma Dive Report 2021, biotech firms actively involved in regenerative drugs and therapies reported funding of USD 14 billion in just the first half of 2021, with an estimated total of USD 19.9 billion for the entire year. There were 16 and 18 new products in development for cystic fibrosis and sickle cell anemia, respectively, in 2021. The burden of rare diseases is growing, and governmental support for the treatment of uncommon diseases is increasing, which is fueling the expansion of the global CGT market. Traditional Pharma vs. Cell and Gene Therapy Manufacturing While chemical medications can be generated in uniformly huge quantities since their production is comparatively well-defined, the CGT manufacturing process is intricate, time-consuming, and frequently results in tiny production volumes. CGT treatments are often produced by growing cells in a bioreactor, a vat designed to maintain carefully calibrated conditions. They require complex biotech manufacturing processes. therefore, it is vital that these types of drugs are managed with care and monitored closely. Because the cells are alive, “every time you run a reactor, the result can be a bit different,” says Chris Love, a chemical engineer in MIT’s Biomanufacturing Research Program. This inherent variability makes the process both expensive and unpredictable. Complex biologic compounds, such as cell and gene therapies, require care and attention throughout the biomedical manufacturing process to ensure that their structure maintains integrity, ensuring the product’s desired integrity and potency. The manufacturing process to turn these cells into living medicine is extremely complex, requiring highly trained scientists to perform long and technical processes. This level of complexity adds a significant cost burden and has been a considerable barrier to realizing the potential of CGT in the clinic. Manufacturing Challenges Many of the challenges biologics manufacturing faces can be attributed to process issues, such as paper-based QA/QC and the slow establishment of the Chemistry, Manufacturing, and Control (CMC) process for CGT. The costs of manufacturing and quality control for those that have made it to market are so high that these potentially curative therapies are expensive and are sometimes only provided as a last resort to patients resistant to other therapies. It is necessary to keep thorough records of the chemical and biological procedures utilized to create each therapy. This record-keeping must be scalable as the medication progresses through the development, clinical trial, and manufacturing phases. However, with CGT, this is typically a manual procedure, resulting in the creation and storage of paper-based records. This approach has several rippling consequences. The subsequent QA and QC processes can only be provided by specialists with access to the physical records, functioning as a bottleneck to scaling. Manual record-keeping is time-consuming and prone to error. Manufacturing requirements are also difficult to scale from the lab. The specificity of these treatments means that cross-contamination can have very serious consequences for patient health, creating a zero-defect requirement in its manufacturing. It is challenging to scale up biologics while maintaining product purity and batch-to-batch consistency from the laboratory levels needed for early analysis and preclinical testing to the larger-scale batches. Despite the encouraging industry initiatives underway, the industry has yet to realize the full potential of digital technologies to bring transformative change to its operational approach. Why Do Cell Therapy Sponsors Select CDMOs? Sponsors of cell therapies have two possibilities for production. Either develop internal manufacturing capabilities or hire a CDMO or CMO. Owning a production site would allow them to acquire internal knowledge, improve procedures, manage manufacturing capacity, and perhaps even save money in the long term

How Flexible is your Serialization Solution? How Flexible is your Serialization Solution? Vivi Korba Upstream Engineer https://youtu.be/PtLhYFWMPL8 Serialization is a constantly changing operation with new requirements (e.g., aggregation), evolving regulations (USA, UAE, etc.), and partner business updates, resulting in a constant increase in complexity, risk, and of course, costs. Multiple companies in the industry are currently offering serialization solutions. But these systems are often complex, inflexible, and unable to efficiently meet the constantly evolving global serialization requirements. Challenge: Avoiding Dependency on All-in-One Vendors Many providers supply not only serialization equipment but also software and integration with a company’s IT infrastructure. However, once such software is installed, it can only be used with that vendor’s hardware. In this circumstance, the pharmaceutical company cannot do business with any other vendor because the software and, in many cases, the hardware are incompatible. This constraint rapidly decreases operation efficiency and negotiation power. Furthermore, it results in ever-increasing costs due to both the by-design inflexibility of the all-in-one vendor systems as well as the ongoing upgrade costs. Solution: Open Serialization Communication Standard (Open-SCS) The Open Serialization Communication Standard (Open-SCS) working group is a partnership of pharmaceutical manufacturers and vendors responding to this call to action. Its purpose is to create an industrial interoperability standard for healthcare package serialization requirements that will increase deployment efficiency while lowering compliance costs. Open-SCS enables a pharmaceutical company to use a “best-of-breed” strategy for various product presentations (carton, bottle, pouch, etc.) and select the most appropriate vendor for the job. Open-SCS is designed to standardize communications across the layers of functionality required to provide a serialization solution based on the ISA-95 paradigm for an automation interface between a company’s control systems. The ISA-95 model specifies a set of “functional layers” that must be present in any correctly developed manufacturing system. Flexibility, durability, dependability, and speedier implementation are all advantages of a layered approach to solution architecture for both the solution developer and the end-user. The Vimachem Level 3 Serialization Site Manager (SSM) The Vimachem Level 3 Serialization Site Manager (SSM) is the world’s largest line and network agnostic serialization software solution with Open and standardized interfaces that ensure unrestricted use with respect to all machines and components already in use at a manufacturer’s site. In addition, its flexible interface technology enables it to connect readily (plug & produce/create) with any line or network system. This feature provides a best-of-breed serialization solution while avoiding the drawbacks of single-vendor systems (vendor lock-in, sluggish response times). Key Benefits: Reduced time to prepare and start production runs. Eliminates incorrectly coded and packaged products as all errors are identified during testing and before live production runs. Minimized unscheduled line stoppages. READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS? READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS? Vimachem Manufacturing Analytics – OEE The Manufacturing Analytics – OEE module is an intelligent Pharma OEE Cloud solution that allows you to collect, store and visualize data across your site / enterprise and apply AI algorithms to optimize production efficiency and product quality. Get started with real-time manufacturing analytics today! Book a Demo

What is Computer Software Assurance (CSA), the FDA’s new approach to CSV? What is Computer Software Assurance (CSA), the FDA’s new approach to CSV? Anna Iliopoulou, MSc Quality Assurance and CSV Manager The purpose of pharmaceutical quality assurance is to ensure that the medication being manufactured will provide the desired effect to the patient. For years, Computer Systems Validation (CSV) documents have played a significant role in ensuring software quality and being able to demonstrate that computer systems work as intended during inspections and audits. However, is that the ultimate goal? Is there a way to maintain or even improve computer systems quality while reducing the documentation efforts? There is and this is the new approach recommended by the FDA called Computer Software Assurance (CSA), which heavily focusing on computer systems tesing as opposed to CSV documentation. In more details, CSV methodology has testersspend 80% of their time documenting the process, whereas only 20% of their time is actually used for testing the quality of the product. On the other hand, CSA guidelines suggest that 80% of the tester’s time will be spent on critical thinking and actual testing, and the remaining 20% of their time will be spent on creating documentation. “The principal objective of software testing is to give confidence in the software.” The FDA’s New Approach to CSV After receiving input from the Food and Drug Administration (FDA) and industry stakeholders, the Center for Devices and Radiological Health (CDRH) began the case to ensure quality. The aim of the initiative was to identify the best manufacturing processes and help medical device manufacturers improve their manufacturing quality levels by changing from being conformity-oriented toward what matters most to the quality of the product. Through a successfulpartnership with companies and stakeholders, the case established manufacturing standards for the medical device industry, offering an industry-clear goal. When the FDA asked the companies that participated in technology investments, what the barriers to realizing value were, the answer was one: CSV. When FDA asked why these companies had not started implementing CSA, their answers were documented and are summarized in the below table: What is preventing the companies from adopting CSA? What are the Main Differences Between the Two Approaches? CSV is an approach that focuses on securing evidence for the auditors rather than concentrating on actual testing. The company will recreate the documentation that has already been created by the vendor, which costs time and effort. Last but not least, there might also be lots of deviations due to the tester’s errors and typos. On the other hand, there’s CSA; it is less burdensome and much faster. Moreover, there is a reduction in deviations due to the tester’s errors. Furthermore, the tester can use critical thinking to ensure the quality of the software. Last but not least, it will help with the risk assessment of the features. Benefits of CSA over CSV Moving away from traditional CSV to CSA represents a cultural shift for validation that reduces documentation time and cost for life sciences organizations that implement software. The FDA has outlined the success companies can achieve with such an enabling technology at their March 2019 case conference. The below table summarizes and highlights the main differences and strengths of the CSA approach. What do you Need to Know when Qualifying a Software or Device Vendor? Many regulated companies in the Pharma and Biotech Industry will choose a vendor to buy software, a device, a solution, etc. Usually, this company will start retesting the software functionality to ensure it is compliant with GAMP5, 21cfr11. According to the FDA guidance, if a vendor’s documentation seems to be of good quality, there should be a focus on making sure that the product will address the expectations rather than reproducing the validation package of the vendor. Following the CSV approach, regulated companies are used to focusing on documentation, manual testing, and showing evidence. This method is used for every part of the tested product, whether it is high-risk functionality or not. However, the CSA approach is more about flexibility with acceptable records of results and the use of critical thinking. Therefore, there is also a need to introduce some new scripting techniques: Scripted – only for higher risk activities of the system that can directly have a software impact on product quality Unscripted – for medium risk features. In this scenario, any deviations should still be recorded as normal Ad-hoc – for low risk, where exploratory testing will be conducted What does the Transition to Computer Systems Assurance mean for the QMS? In Quality Management Systems (QMS) applications, the risk to product quality and patient safety is much lower and therefore does not require the same level of testing. The guidelines acknowledge industry changes and recognize the distinct levels of risks associated with a variety of applications. The most common industry software is Category 4 Configured software, which allows firms to use verification tools for software changes without writing to meet the business process needs. This change saves time, money, and resources. Is it Worth Transitioning – What are the Key Facts that an Organization Needs to Consider? Revise the current policies to align with this new CSA approach. Reconsider the way your company works and change it from being a compliant mentality to being quality centered Use to your benefit your vendor’s existing validation package Use automation tools to automate assurance activities Familiarization with the use of the product Get to understand the riskprone characteristics of the product. FDA supports the computer system assurance approach It will reduce documentation by up to 80% No new regulations need to be introduced for this approach Is CSA Going to Affect GAMP? Adopting CSA is not introducing new concepts. Its only purpose is to focus on testing and not documenting low-risk requirements. Will this Affect 21 CFR Part 11 and Audit Tables? The CSA approach is applicable to 21 CFR Part 11, but its purpose is to minimize its focus. Whereas the concern is gathered

- 1

- 2